Offshore wind turbines must be floating

Welcome to the offshore wind farm in Kattegat - TetraSpar

Floating wind farms can produce energy in deep water

These floating offshore wind farms allow us to exploit ocean areas previously inaccessible to traditional offshore wind turbines fixed to the seabed. Future offshore wind turbines represent a breakthrough technology that can maximize the utilization of the world's wind resources and contribute significantly to the global energy supply.

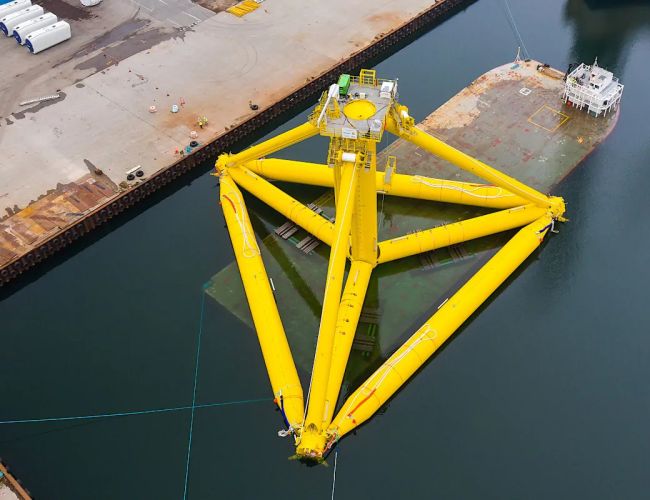

At the Port of Grenaa, we can provide the ideal space for handling and shipping large wind turbine components - as was the case with the development of the floating offshore wind turbine TetraSpar.

-

Introduction to TetraSpar

The TetraSpar offshore wind turbine structure was designed by Stiesdal Offshore and manufactured by the wind turbine experts at Welcon. It was transported to the Port of Grenaa during the summer of 2020. The assembly took place in October and November of the same year.

The project has utilized Welcon's advanced production capacity and the logistical strengths of the Port of Grenaa, which together have made it possible to realize this groundbreaking floating offshore wind turbine called TetraSpar.

The TetraSpar Demonstrator is owned by Shell, RWE, TEPCO and Stiesdal.

-

The concept behind

There are three main concepts in floating offshore wind:

- A spar that balances like a keelboat with the center of gravity below the center of buoyancy.

- A semi-submersible that maintains balance via buoyancy wakes set up in the corners

- A TLP (Tension Leg Platform) that maintains balance by a balance of forces between buoyancy on the foundation and powerful anchors on the seabed.

-

Pre-assembly

Ideal development area for assembling large structuresThe assembly of TetraSpar took place at the pre-assembly site at the Port of Grenaa. This site was chosen due to its ideal location and capacity. Pre-assembly is a large, flat area at the quayside, which allows the project to be carried out without the need for special facilities.

-

Facilities

Pre-assembly is a well-organizedproject area with the following facilities:

- Good distance to housing

- Exclusive quay areas built of reinforced concrete with high load-bearing capacity

- Installation within ISPS area

- Office facilities

- 30,000 m2 new port area

- Supply of 20 MW green shore power

- Jack-up area with reinforced seabed for installation vessels

The foundation is loaded

After the assembly of the floating wind turbine, large cranes are used to lift and place the turbine on a submersible barge. The barge is lowered into the water to create a stable platform, after which the turbine is secured safely. The barge is then raised back to its normal height and the turbine is ready to be transported out to sea.

TetraSpar is the groundbreaking ceremony for future offshore wind farms

The TetraSpar offshore wind turbine marks the beginning of a new era in offshore wind farms. The assembly of this pioneering floating wind turbine has just been completed at the Port of Grenaa, a location that could become a hub for similar projects in the future. The Port of Grenaa has the necessary facilities and space to house and support several of these advanced energy production facilities, making it an ideal base for the future development of offshore wind technology.

TetraSpar is distinguished by its ability to float on the water, enabling placement in deep water where traditional offshore wind turbines fixed to the seabed cannot be installed. This means we can take advantage of stronger and more stable wind conditions far from shore, increasing the efficiency and reliability of wind energy production.

Ideal sparring partner for floating wind

With extensive infrastructure, including large assembly stations and deep harbor basins, the Port of Grenaa is perfectly positioned to handle the assembly and shipping of floating wind turbines like TetraSpar.

With TetraSpar, the Port of Grenaa has not only contributed to an important milestone in renewable energy, but also paved the way for future projects that will continue to utilize and develop this innovative technology.

Want to know more?